Naroda, Ahmedabad, Gujarat

- GST NO. : 24AHNPC7685H1Z1

Machine Job Works

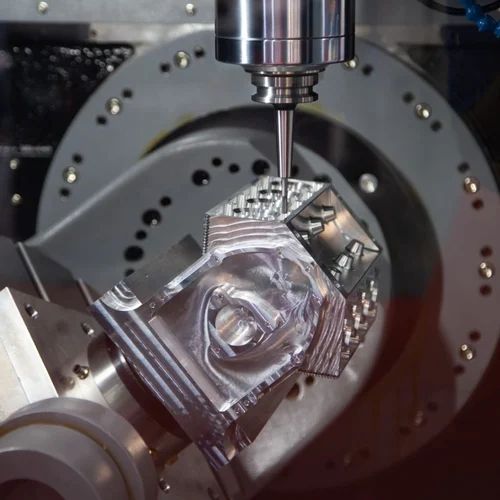

Leading Manufacturers, Exporters, Wholesaler of 4 Axis CNC Milling Machining Job Work, 5 Axis CNC Machining Job Work, CNC Aluminum Turning Machining Job Work, CNC Stainless Steel Turning Machining Job Work, Horizontal Boring Machine Job Work, Precision Lathe Machine Job Work and VMC Machine Job Work from Ahmedabad.

4-axis CNC milling machining involves using a computer numerical control (CNC) system to manipulate cutting tools across four axes: X, Y, Z, and an additional rotational axis (A). This process enables the production of complex and precise components by allowing for the cutting and shaping of materials from multiple angles. Commonly used in aerospace, automotive, and medical industries, 4-axis CNC milling enhances efficiency and accuracy in creating intricate designs, reducing the need for multiple setups. It is particularly effective for tasks such as drilling, contouring, and engraving, providing high-quality finishes and improved production speeds.

5-axis CNC machining involves the use of computer numerical control (CNC) systems to manipulate cutting tools across five axes simultaneously: X, Y, Z, and two additional rotational axes (A and B). This advanced capability allows for the creation of highly complex and precise parts with intricate geometries, reducing the need for multiple setups and manual repositioning. Widely used in aerospace, automotive, and medical industries, 5-axis CNC machining offers superior accuracy, efficiency, and surface finishes. It is ideal for manufacturing components with tight tolerances and complex contours, enabling the production of sophisticated parts in a single, continuous operation.

CNC aluminum turning machining involves using a computer numerical control (CNC) lathe to precisely shape aluminum workpieces by rotating them against cutting tools. This process is essential for producing cylindrical and symmetrical parts such as shafts, bolts, and custom components. CNC turning offers high precision, repeatability, and efficient production, making it ideal for industries like aerospace, automotive, and electronics. The use of aluminum, known for its lightweight and corrosion-resistant properties, further enhances the utility of the parts produced. CNC turning ensures tight tolerances, smooth finishes, and faster turnaround times, optimizing both small-scale and large-scale manufacturing operations.

Transform your ideas into precise metal components with our CNC turning expertise. We specialize in machining stainless steel, ideal for projects requiring strength and corrosion resistance.

Our services include:

- CNC turning: Achieve intricate details and tight tolerances on your parts.

- Fast turnaround: Get your projects completed quickly to keep your production on track.

- Custom solutions: Work with our engineers to bring your designs to life.

- Scalability: We handle small orders and large volume production runs.

Perfect for a wide range of applications:

- Medical devices

- Aerospace parts

- Automotive components

- Construction hardware

- And more!

Get a free quote today! Let's discuss your CNC stainless steel turning needs and turn your vision into reality.

Horizontal boring machine job work involves using a horizontal boring machine (HBM) to accurately enlarge holes in heavy and large workpieces. This process is crucial in industries like aerospace, automotive, construction, and heavy equipment manufacturing, where precision and strength are essential. HBMs can handle various tasks such as drilling, milling, and tapping, making them versatile for creating precise bores, cavities, and complex geometries. The machines offer high rigidity and stability, ensuring tight tolerances and smooth finishes on large components. Horizontal boring enhances efficiency, reduces manual labor, and ensures the production of high-quality, custom parts suited for demanding applications.

Precision lathe machine job work utilizes high-precision lathes to manufacture intricate cylindrical and symmetrical parts from various materials like metals, plastics, and composites. This process involves rotating the workpiece against cutting tools that remove material with precision, achieving tight tolerances and smooth finishes. Precision lathes are essential in industries such as aerospace, automotive, and electronics for producing components like shafts, bushings, and fittings. They ensure accurate dimensions, concentricity, and surface quality, meeting stringent quality standards. Precision lathe machine job work enhances production efficiency, reduces lead times, and supports the fabrication of custom parts and prototypes tailored to specific engineering requirements and applications.

Our workshop is equipped with top-of-the-line VMC (Vertical Machining Center) machines, ready to tackle your most demanding projects. We specialize in precise, high-quality machining for a wide range of components and parts.

Our VMCs offer unmatched versatility, allowing us to handle complex designs and intricate features on various materials. Whether you need tight tolerances or challenging angles, our skilled machinists and advanced VMC technology can deliver exceptional results.

We understand the importance of efficiency. Our streamlined processes and focus on precision minimize turnaround times, ensuring your project stays on schedule. Plus, our file compatibility with popular CAD formats allows for seamless integration with your design workflow.

Get a free quote today and experience the difference VMC machining can make. Our commitment to quality and competitive pricing ensures you receive exceptional value. Let us turn your concepts into reality with unmatched precision and speed.